The wax goes on to supply candle wax and petroleum jelly though the dewaxed oil purifies in to the attractive lube oil foundation inventory. Issues that crop up from this process originate from picking out which kind of solvents to employ. Most refineries use MEK Regardless that propane can be employed from various areas of the process, cut costs, enhance filtration prices.

Within this guide, we’ll stop working the solvent dewaxing process definition, clarify how it really works, and check out its essential role in industrial apps.

No matter whether you’re sourcing specialty lubricants or engineering petroleum-based solutions, knowing solvent dewaxing is essential to optimizing your supply chain.

Modern-day methods combine solvent Restoration systems, lowering environmental effects by around 30% when compared with traditional strategies.

The faculty of Earth and Mineral Sciences is committed to producing its Internet websites accessible to all customers, and welcomes responses or solutions on access improvements.

The layer of wax (filter cake) to the drum is scraped from the filter by a blade and carried away within a solvent stream into a steam-stripping unit to Get well and recycle the solvent divided within the wax product. The wax solution, named slack wax, may be used to help make paraffin wax for candles, microwax Employed in the cosmetics field, and petrolatum for petroleum jelly. The dewaxed oil from the filtration unit can also be steam stripped to recover the solvent to provide the lube oil base stock.

By dissolving and crystallizing waxes, the process guarantees the final item maintains fluidity and stability across numerous functioning disorders.

Within an era in which industrial efficiency and item quality are non-negotiable, solvent dewaxing has emerged as a cornerstone technology for refining superior-general performance products.

Pharmaceutical and food items packaging waxes demand from customers extremely-pure dewaxed outputs to meet protection restrictions.

Catalytic dewaxing can be a chemical process that, by character, is actually a conversion process. It takes advantage of catalytic cracking of n-paraffins, but For the reason that function is to remove wax, it is assessed being a separation process. There's not much depth to this process although it does use hydrogen addition to forestall coking.

Solvent dewaxing is indispensable across industries demanding substantial-overall performance petroleum derivatives:

It is clearly The obvious way to dewax the feedstocks because it leads to an item with reduced pour details, higher generate, and higher security. Catalytic dewaxing also permits the production of light distillates which Paraffin Block Wax Forming Machine include gasoline Because the n-paraffins are cracking.

Determine five.12 displays a general scheme of solvent dewaxing that works by using phase-sensible refrigeration with the feedstock following it truly is blended Using the solvent. The lowest temperature Employed in the refrigeration cascade depends on the desired pour level with the lube oil's foundation stock item. Upon refrigeration, wax compounds solidify to sort crystals. Wax crystals are carried during the solvent to a rotary filter, in which wax is separated over a filter fabric masking the rotating drum.

This technique is favored read more for its precision and scalability, making it a cornerstone of contemporary refineries.

Solvent dewaxing is often a refining technique that removes waxes (extended-chain hydrocarbons) from petroleum merchandise working with a mix of solvents and managed cooling. These waxes solidify at decreased temperatures, that may impair product overall performance in programs like engine oils or industrial greases.

Meta Description: Find out the science guiding solvent dewaxing, its action-by-action process, and why It can be important for industries like Dongguang Tiancheng Machinery Factory lubricant production and petroleum refining. Find out how this method boosts item purity.

Solvent website dewaxing is really a physical process that takes advantage of refrigeration, scraping techniques, and methyl ethyl ketone (MEK) and propane solvents to different the feedstocks and develop a important products. The MEK solvent as well as deasphalted oil Blend in the primary stage and go through check here a number of refrigeration processes at distinct temperatures to form wax crystals, which are then transported to your rotary filter the place a filter cloth separates the wax with the oil + solvent.

By crystallizing and separating wax molecules at managed temperatures, it assures the ultimate product or service meets stringent viscosity, pour issue, and thermal balance standards.

Posted on June 21, 2014 by Graham Deever Dewaxing is a separation process that can take advantage of deasphalted oil (DAO) and significant vacuum gas oil (HVGO) with the vacuum distillation tower as feedstocks in generating lubricating oil foundation stock and, to some extent, distillate fuels for example gasoline.

Please ship comments or tips on accessibility to the site editor. The positioning editor may also be contacted with inquiries or opinions about this Open up Instructional Resource.

In case you’re new to petroleum refining or lubricant producing, you’ve most likely encountered the phrase “solvent dewaxing.�?This important process ensures solutions like lubricating oils, greases, and specialty waxes fulfill stringent high quality expectations.

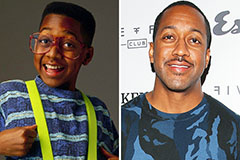

Jaleel White Then & Now!

Jaleel White Then & Now! Neve Campbell Then & Now!

Neve Campbell Then & Now! Andrea Barber Then & Now!

Andrea Barber Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now! McKayla Maroney Then & Now!

McKayla Maroney Then & Now!